About Heavy Duty Rotary Index Drives

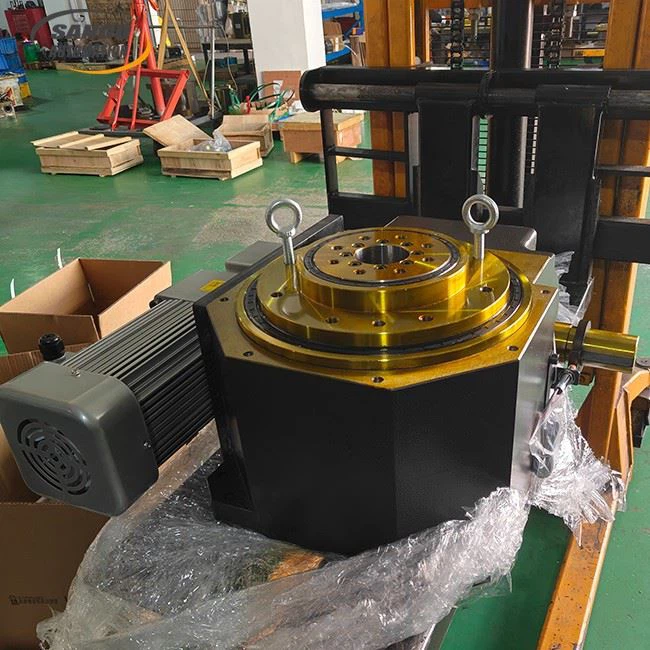

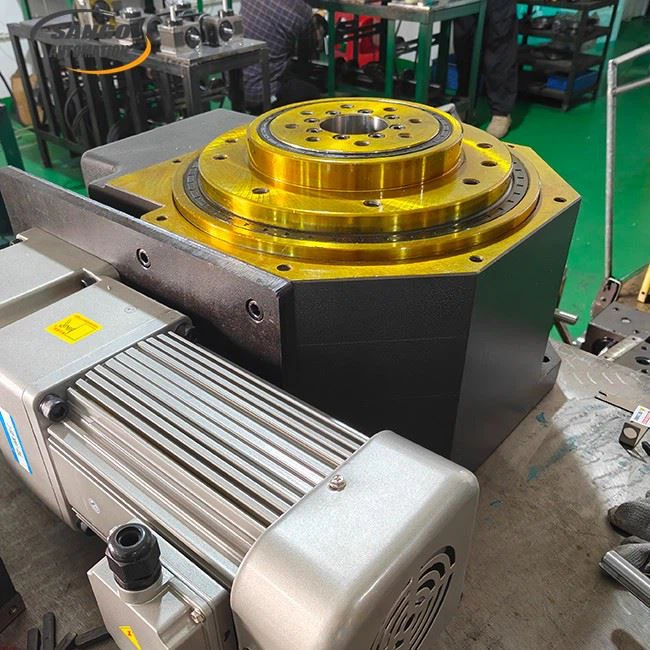

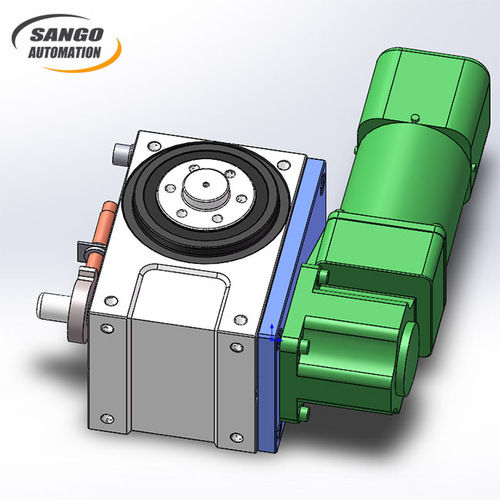

Our Heavy Duty Rotary Index Drives are designed for high-load, high-precision automation scenarios. Its design follows a core principle: maximizing load-bearing capacity and ease of system integration while ensuring indexing accuracy and long-term reliability.

To achieve this, we have made improvements to three key components: Globoidal Cam, Roller Gear Cam, and Housing.

Globoidal Cam

Made of 38CrMoAl, nitrided and case hardened, with a hardness of up to 60-67 HRC.

Roller Gear Cam

Selected GCr15 bearing steel, hardened to a hardness of 58-62 HRC, forming a high-rigidity, low-wear meshing pair with the cam.

Housing

Housing is cast in gray cast iron HT300, and the graphite contained in the material effectively absorbs vibration energy during heavy-duty operation.

Product Features

Capable of withstanding heavy loads

The output shaft adopts a reinforced structure and high rigidity bearings to withstand extremely large axial and radial loads. The maximum static load is up to 6500 kgf, and the bearing capacity is 23 times that of the standard model in the same class, especially suitable for large molds, heavy workpiece handling and high-load automation scenarios.

High precision and long life

It adopts precision cam and reinforced roller design to ensure high indexing positioning accuracy and smooth operation. The optimized heat treatment and surface treatment process significantly improves the wear resistance and fatigue strength of the components, ensuring the long-term stable operation of the equipment under heavy load conditions.

Hollow shaft structure

The output shaft is a large-diameter hollow design with a fixed raised disk face. Users can directly pass air pipes, cables, etc. through the axis to achieve neat internal wiring, greatly save equipment space, and improve the integration and aesthetics of the overall system.

Support deep customization

In addition to the standard Heavy Duty Rotary Index Drives, we offer a full range of customizations from cam curves and roller specifications to heat treatment processes and surface coatings. The design and process can be adjusted to your load characteristics, motion profiles, and environmental requirements to ensure that the indexer is a perfect match for your application.

Models And Technical Parameters

Our Sango Heavy Duty Rotary Index Drives series consists of eight standard models, namely 80DT, 110DT, 140DT, 180DT, 210DT, 250DT, 350DT, and 450DT. The following are the relevant parameters and drawings of these eight standard models. But we can customize our products to suit your conditions, making our Heavy Duty Rotary Index Drives more tailored to your specific conditions.

|

Parameter

|

80DT

|

110DT

|

140DT

|

180DT

|

210DT

|

250DT

|

350DT

|

450DT

|

|

Stations

|

2,4,6,8,12,16,32,64,etc

|

|

Allowable thrust load on output shaft

|

520 kgf

|

860 kgf

|

1050 kgf

|

1500 kgf

|

1950 kgf

|

2500 kgf

|

4500 kgf

|

6500 kgf

|

|

Allowable radial load on output shaft

|

220 kgf

|

420 kgf

|

720 kgf

|

1100 kgf

|

1520 kgf

|

1800 kgf

|

3300 kgf

|

4500 kgf

|

|

Allowable thrust load on input shaft

|

220 kgf

|

300 kgf

|

500 kgf

|

1200 kgf

|

1570 kgf

|

1900 kgf

|

2800 kgf

|

3300 kgf

|

|

Max. repetitive bending force on input shaft

|

160 kgf

|

250 kgf

|

350 kgf

|

960 kgf

|

1130 kgf

|

2250 kgf

|

3800 kgf

|

4500 kgf

|

|

Indexing accuracy

|

30 arc sec

|

30 arc sec

|

30 arc sec

|

30 arc sec

|

30 arc sec

|

30 arc sec

|

30 arc sec

|

30 arc sec

|

|

Weight

|

20 kg

|

50 kg

|

80 kg

|

180 kg

|

450 kg

|

500 kg

|

1200 kg

|

2240 kg

|

Applications

The heavy duty rotary index drives we produce are currently widely used in the following areas.

Heavy-duty metal forming

In the continuous stamping of large sheet metal parts such as automotive chassis and doors, high vertical pressures can be subjected to during die exchange and workpiece indexing.

Packaging & Filling Machinery

High precision and durability at high speeds make Heavy Duty Rotary Index Drives commonly used for filling, capping, and labeling chemical drums, oil drums, and other containers.

New energy battery manufacturing

In the power battery module/pack production line, it is used for welding, assembly, inspection and code scanning stations for heavy battery packs. Cell alignment accuracy can be maintained under frequent start-stops.

Sturdy Metal ConstructionOur Heavy Duty Rotary Index Drives are crafted from premium metal materials, ensuring long-lasting service even in demanding industrial settings. The robust build maximizes strength and stability, reducing wear and tear over time.

Single Phase, Motor-Driven EfficiencyOperating at 220 Volts in a single-phase setup, these rotary index drives deliver smooth, consistent motion. The reliable motor drive system ensures precise indexing without the need for remote control, offering easy integration into most industrial setups.

Assurance with One-Year WarrantyEach unit is backed by a one-year warranty, reflecting our confidence in the product's quality. Customers can rely on dedicated support and service throughout this warranty period, ensuring a trouble-free experience.

FAQ's of Heavy Duty Rotary Index Drives:

Q: How does the Heavy Duty Rotary Index Drive operate?

A: The device operates using a motor drive system with a 220 Volt single phase power supply, enabling smooth and precise index positioning in automated processes without the need for remote control.

Q: What are the benefits of using this rotary index drive?

A: Users benefit from its reliable metal construction, good quality performance, and the assurance of a one-year warranty. It is designed for durability and consistent operation in heavy-duty settings, making it ideal for industrial use.

Q: When should I consider implementing a rotary index drive in my operations?

A: A rotary index drive should be considered when your application requires precise and repetitive motion between set positions, such as in assembly lines or automated machinery, where accuracy and efficiency are critical.

Q: Where are these rotary index drives mainly supplied and exported from?

A: These drives are distributed, exported, and supplied by a reputable manufacturer in India, serving customers domestically and internationally.

Q: What is the installation process for these devices?

A: The installation process involves mounting the rotary index drive securely to your machinery, wiring it to a 220 Volt single-phase power supply, and integrating it into your control system, following the manufacturer's guidelines.

Q: How can I ensure the longevity and optimal usage of this drive?

A: Regular maintenance, such as checking connections and ensuring the drive is not overloaded, will ensure optimal performance. Always operate within the specified voltage and environmental conditions for best results.

Q: What features distinguish this rotary index drive from others on the market?

A: Distinctive features include its good quality build, reliable metal materials, single-phase 220 Volt operation, and the support of a one-year warranty. Its robust construction and dependable performance set it apart, especially for heavy industrial applications.

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese