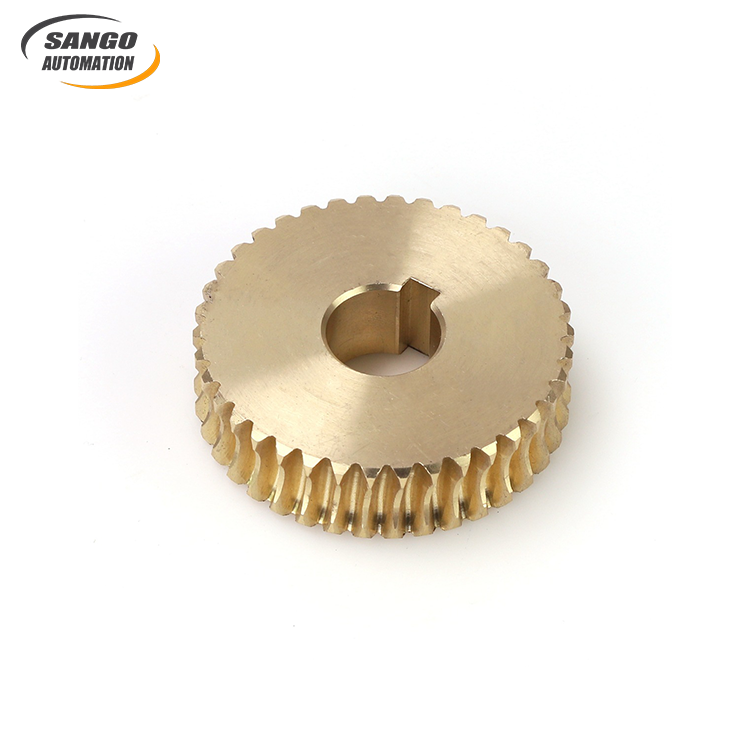

ISO 5 Precision Custom Metal Worm Gear

ISO 5 Precision Custom Metal Worm Gear Trade Information

- Minimum Order Quantity

- 5 Pieces

- FOB Port

- Shenzhen

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 30 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, South America, Eastern Europe, Western Europe, Middle East, Australia, Central America, North America, Africa

- Main Domestic Market

- All India

About ISO 5 Precision Custom Metal Worm Gear

Product Features

Precision Advantages

ISO/DIN/GB Grade 5 precision (gear tolerance 5m): 40% reduction in backlash compared to traditional Grade 6 precision, with a 15% increase in transmission efficiency. Single-lead worm gear backlash of 3-5 arc minutes, adjustable to 1-3 arc minutes for double-lead, specifically designed for precision transmission applications such as servo motors and robot joints.

Utilizing shaving process + helix angle optimization, surface roughness Ra 0.8 m, with noise levels below 60 dB for 1-2 head worm gears (conventional 7-grade precision noise 65 dB).

Grade 5 precision worm gears have a fatigue life of 10^6 cycles (Grade 6 precision is 510^5 cycles), with finite element analysis verifying more uniform tooth surface contact stress distribution.

Full specification coverage and material advantages

Standard module: 0.54 mm (customizable non-standard modules from 0.36 mm), reduction ratio 1080 (customizable 5100).

Matching worm gears and non-standard customization capabilities

Worm gears are processed on the same production line, ensuring matched tooth surface hardness and high meshing accuracy. Custom processing available for special tooth profiles (involute/normal straight profile), non-standard installation distances (0.01mm tolerance), and irregular hole diameters (spline holes/step holes), as well as corrosion-resistant coatings (Ni-P plating), high-temperature alloys (e.g., Inconel), and noise-optimization (tooth tip profiling) customization requirements.

Price 10.0 USD ($)/ Piece

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia, South America, Eastern Europe, Western Europe, Middle East, Australia, Central America, North America, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry