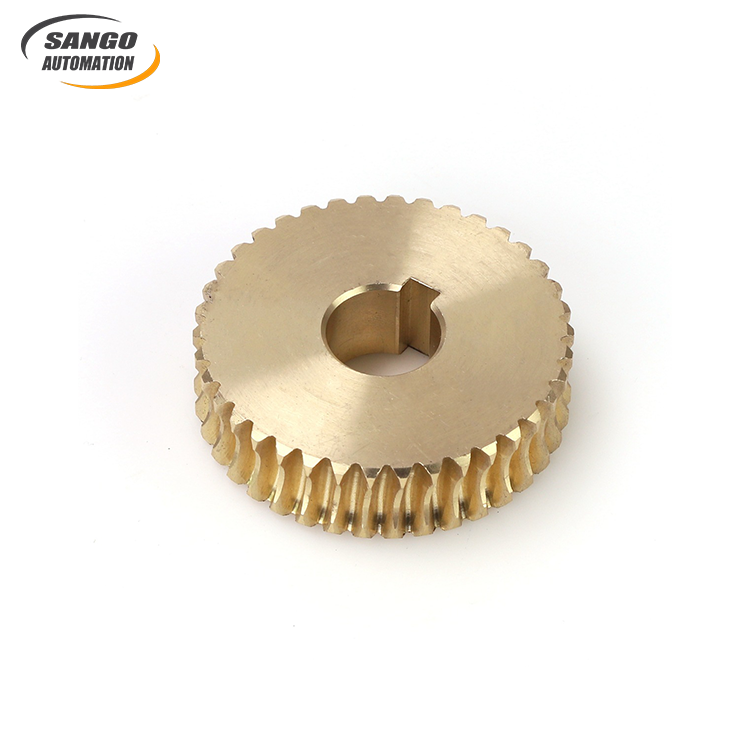

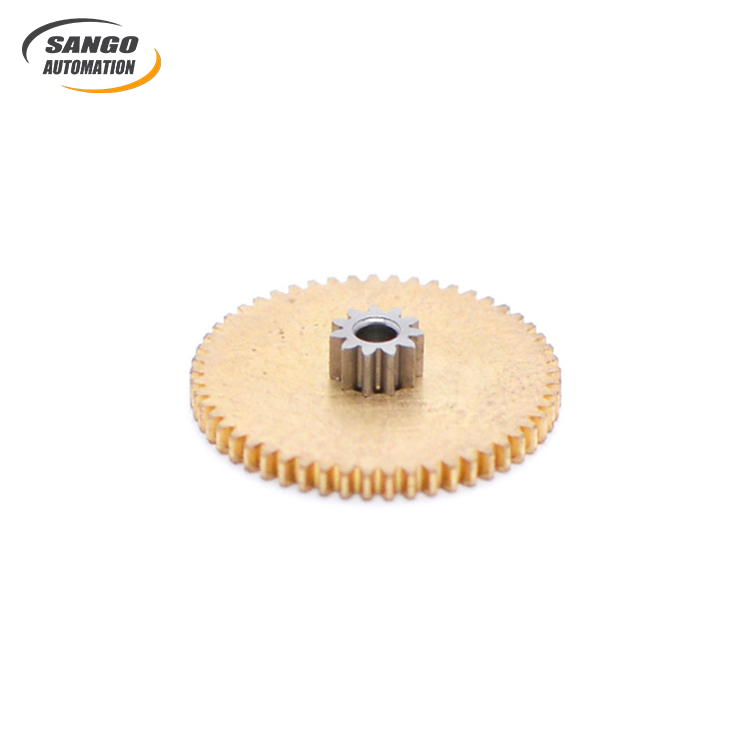

Metal Pinion Gear

Metal Pinion Gear Trade Information

- Minimum Order Quantity

- 5 Pieces

- FOB Port

- Shenzhen

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 30 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Metal Pinion Gear

Product Features

Wear-resistant torque reinforcement

Laser-hardened involute splines (HRC55+) improve torque transmission efficiency, while wear-resistant keyways reduce inner shaft wear (suitable for pinion gears in heavy-duty gearboxes).

The double-top-line locking structure at the shaft end (200% design torque without loss of locking) eliminates the risk of slippage in open transmission scenarios such as construction machinery.

Precision Heat Treatment and Quality Inspection

Vacuum carburizing layer depth 0.005mm (HRC60-62), -196C deep cryogenic treatment improves wear resistance by 30% (suitable for high-speed requirements of robot joints).

Zeiss coordinate measuring machine full inspection (tooth profile error 4m), achieving ISO 5-grade precision (meeting precision requirements for aviation instruments and other applications).

Full-parameter customization capability

Module range: 0.15.0 mm (supporting 0.08 mm micro-module customization), tooth count: 825 (including designs with fewer than 14 teeth), pressure angle: 20/25 selectable.

Special material customization: 17-4PH stainless steel (corrosion-resistant), 7075 aluminum alloy (lightweight model car small gears).

Price 5.0 USD ($)/ Piece

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry