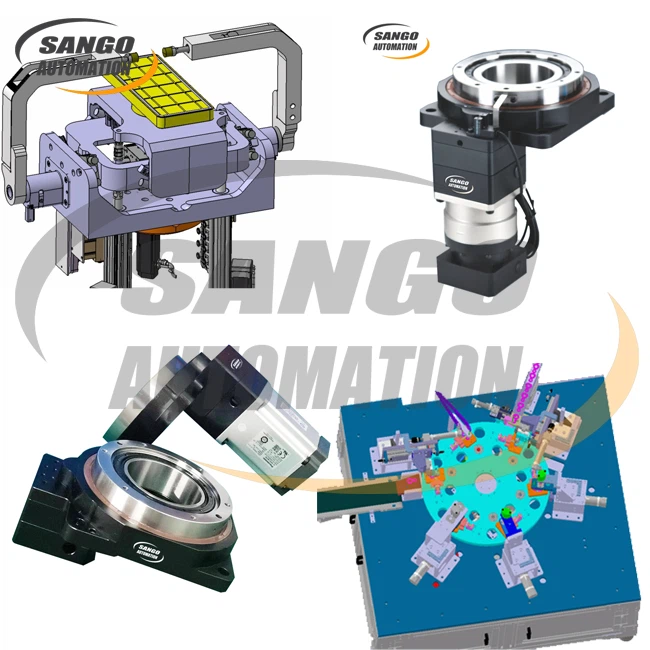

About Hollow Rotating Table For Packaging Machine

Sango Automation has a strong production and R&D capability. The products of our company have exported to many countries. Hollow rotating tables of Sango Automation are purchased by many customers, because hollow rotating tables of our company have high quality and could be applied widely in many fields. Hollow rotating tables are widely applied in packing machine. For the application of packing machine, Sango Automation also can provide many other products, such as cam indexer, harmonic drives , planetary gearboxes and other precision components.

Application in Packaging Machine

Material direction adjustment

In the link of packaging machines, such as feeding, boxing or packing, hollow rotating table can control rotation angle of the material precisely and ensure materials enter the packaging station in the correct orientation. For example, in pharmaceutical packaging, hollow rotating table can be used to adjust the orientation of medicine bottles. It make their labels face the same direction and easier to seal and pack.

Labeling and sealing positioning

Hollow rotating table can drive the packaging container to rotate, it works with labeling machine or sealing equipment and make precise operations of labeling and sealing operations can be achieved. For example, in beverage bottle packaging, a rotating table enables bottles to rotate at a constant speed. The labeling machine can accurately apply labels to the designated positions on the bottle body, at the same time, the sealing equipment can also complete the sealing at an appropriate angle. So hollow rotating table can improve quality and efficiency of packaging.

Multi-station collaborative operation

In a multi-station packaging machine, hollow rotating table can achieve rapid switching between workstations. For example, In an automatic cartoning machine, hollow rotating tables transfer the product from one workstation to another, the operations such as boxing, sealing and labeling are completed in sequence. So hollow rotating table can reduce manual intervention and increase the level of production automation.

Sorting and Directional Conveying

Combined with sensors and control system, the rotating table can sort and transport packaged items directionally. For example, after the packaging of the express package is completed, hollow rotating table rotate the package to the designated conveyor channel based on the size, weight or destination information of the package. So hollow rotating table can achieve classification and directional transportation and improve the efficiency of logistics.

Equipment integration and wiring convenience

The hollow structure of hollow rotating table allows cables, air pipes, etc. to pass through the center. It avoids the problem of cable entanglement in traditional rotating mechanisms and make the wiring of the packaging machine more concise and regular. The machine will be easy to maintain and upgrade. Meanwhile, the compact design of hollow rotating table saves equipment space and improve the overall layout flexibility of the packaging machine.

Operating Principle

The structural principle of the hollow rotating table

The rotation effect is achieved through the meshing of gears between the inner and outer circular rings.

The gears on the inner ring mesh with the gears on the outer ring, the rotational force is transmitted to the inner or outer ring via a transmission mechanism.

How to select a hollow rotating table

Provide working conditions of your equipment

1. Weight of loading

2. Diameter of turntable

3. Max speed. Or how many seconds to rotate how many degrees?

4. Drawing or photo of your applicaiton

5. Horizional, vertical or suspension installation?

6. Quantity

Versatile Integration for Automated PackagingOur Hollow Rotating Table seamlessly integrates with various automated packaging machines. Its metal construction ensures durability, while the precision motor-driven system optimizes package orientation for efficient sorting or filling. Supported by a 20-month warranty, this equipment is available throughout India through our extensive distributor and supplier network.

Efficient and Reliable PerformanceUtilizing a 220-volt motor drive, the Hollow Rotating Table offers consistent, high-speed rotation for uninterrupted packaging line operations. Its hollow design allows for easy cleaning and minimal maintenance. Built for demanding industrial environments, this table ensures improved workflow and increased productivity in packaging applications.

FAQ's of Hollow Rotating Table For Packaging Machine:

Q: How is the Hollow Rotating Table used in automated packaging equipment?

A: The Hollow Rotating Table is used to streamline the flow of products on conveyor lines, orienting or accumulating items for efficient further processing, such as sorting, filling, or labeling, making it essential for automated packaging operations.

Q: What are the main benefits of choosing a motor-driven hollow rotating table?

A: A motor-driven hollow rotating table ensures consistent rotation, precise product handling, and higher operational efficiency, reducing manual intervention and increasing throughput on automated packaging lines.

Q: When should I consider installing this table in my packaging line?

A: You should consider installing the Hollow Rotating Table when your packaging operations require faster product orientation, accumulation, or transfer between processing stages, particularly when aiming to automate and scale your workflow.

Q: Where is this product available for purchase in India?

A: The Hollow Rotating Table is distributed, supplied, exported, manufactured, and traded throughout India. You can obtain it from authorized distributors, exporters, manufacturers, and suppliers specializing in packaging machinery.

Q: What is the process for installation and integration with existing machinery?

A: Installation typically involves connecting the table's motor drive to a 220-volt power source and interfacing the unit with your existing conveyor or packaging system. Our technical support ensures seamless integration and setup as per your line's requirements.

Q: How does the 20-month warranty benefit customers?

A: The 20-month warranty offers extended assurance against manufacturing defects or unexpected malfunctions, providing you with reliable service support and peace of mind for nearly two years after purchase.

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese