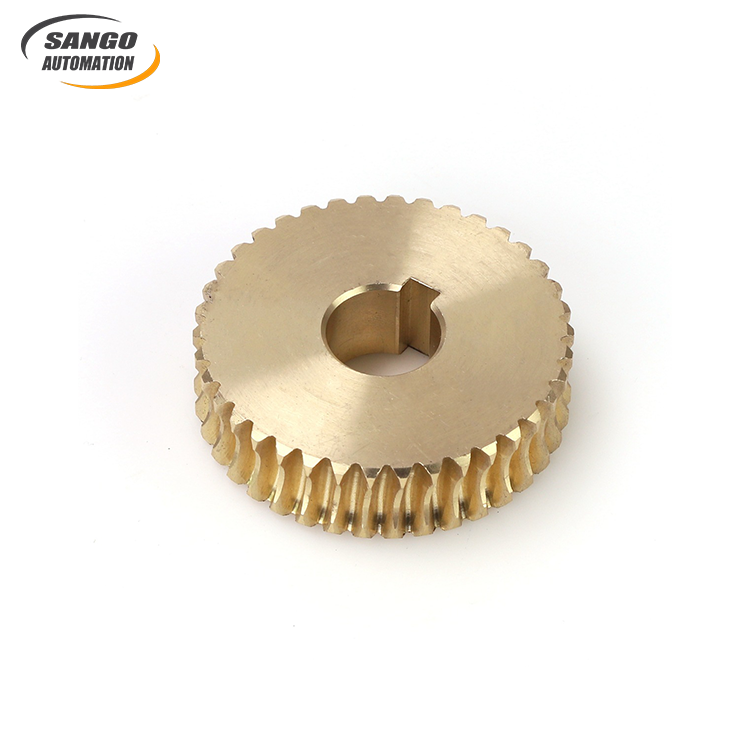

About Inner Gear

Product Features

Exceptional Precision

Our gears achieve ISO/DIN Class 5 precision, ensuring flawless tooth profiles and smooth meshing.

Advanced Manufacturing

Our core equipment utilizes the Kashifuji KPS30 power shaving machine from Japan.

Compact & Space-Saving

Internal gears, also known as internal meshing gears, enable compact structural design. This meshing configuration achieves higher gear ratios and torque output within limited space.

High Torque Capacity

We optimize tooth profiles and load distribution to enhance torque and shock load resistance, extending service life.

Fully Customizable

From material selection (alloy steel, stainless steel, specialty materials) and heat treatment processes (carburizing, nitriding) to custom module, tooth count, and special tooth profiles, we manufacture entirely according to your drawings and application requirements.

Technical Parameters

| Parameter |

Specification & Capability |

| Gear Precision |

ISO / DIN / GB Level 5 |

| Module |

0.1 5.0 |

| Tip Diameter |

3mm 300mm |

| Materials |

Alloy steel (20CrMnTi, 42CrMo), Stainless Steel, customizable according to customer requirements |

| Heat Treatment |

Carburizing, Nitriding, High-Frequency Hardening |

| Surface Hardness |

HRC 58-62 or according to process requirements |

| Processing Technology |

Power Skiving, Gear Shaping, WEDM |

| Surface Finish |

Grinding, Black Oxide, Plating |

Our Technical Edge

Core Equipment - Kashifuji Gear Skiving Machine KPS30

Ultra-precision machining covers every stage: From precision grinding and milling with a 0.005mm accuracy to ultra-mirror finishing with 0.002mm accuracy, tooth profile accuracy is guaranteed throughout the entire process.

Strict quality inspection: We utilize professional gear testing equipment to conduct 100% inspection of key parameters such as tooth profile, pitch, and runout, ensuring that every product meets the required standards.

Superior Strength and DurabilityEngineered from alloy steel and treated with advanced heat processes such as carburizing and quenching, our inner gear provides exceptional toughness and longevity. Its case-hardened surface not only ensures minimal wear but also maintains structural integrity under intense operational loads in planetary gearboxes.

High Efficiency and Low Noise OperationAchieve impressive mechanical performance with over 98% efficiency and a design focused on reduced noise levels. This gear supports precise, reliable energy transfer at up to 5 kW rated power and 1500 RPM, making it ideal for smooth, quiet industrial operations in both new installations and retrofits.

Versatility for Industrial ApplicationsThe inner gear is suitable for a broad range of industrial uses, thanks to its bidirectional capability, adherence to ISO/DIN standards, and compatibility with various planetary gearbox arrangements. Its custom output speed options and standard size availability make integration seamless for manufacturers, exporters, and suppliers.

FAQ's of Inner Gear:

Q: How is the inner gear manufactured to ensure durability and precision?

A: The gear is crafted from high-quality alloy steel and undergoes case hardening with carburizing and quenching. This process enhances surface hardness while retaining a tough core, ensuring long service life and precise operation under heavy duty industrial demands.

Q: What are the primary applications for this inner gear?

A: This inner gear is primarily designed for use in planetary gearboxes across a range of industrial applications, where high efficiency, low noise, and reliable torque output are essential.

Q: When should I choose this inner gear for my gearbox system?

A: Select this gear when your application requires standard size inner gears with 48 teeth, robust construction, high efficiency (over 98%), and output torque demands up to 500 Nm. It is suitable for both new machinery and replacement in existing systems.

Q: Where is this inner gear available and who can supply it?

A: This inner gear is distributed, exported, manufactured, and supplied in India by industry-leading companies, ensuring availability for a variety of industrial sectors both domestically and internationally.

Q: What is the process of surface treatment for this inner gear?

A: The gear undergoes case hardening, which involves carburizing the surface followed by quenching. This process increases wear resistance and durability, making the gear suitable for continuous, intensive industrial operation.

Q: How is the gear installed and used in planetary gearbox arrangements?

A: The gear's standard sizing and design ensure straightforward integration into planetary gear systems. It functions as a core transmission element, enabling smooth bidirectional transfer of torque while maintaining optimal efficiency and low noise.

Q: What are the key benefits of using this case-hardened inner gear in industrial settings?

A: Users benefit from high mechanical efficiency, reduced operational noise, extended lifespan due to superior surface hardness, and the flexibility to use the gear in various industrial applications that demand reliable, sustained performance.

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese