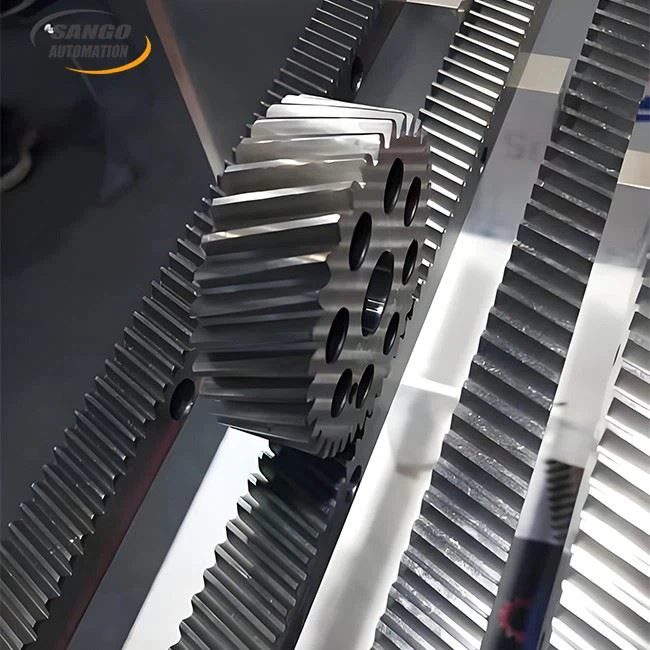

Gear Rack

Gear Rack Specification

- Product Type

- Gear

- Gear Type

- Rack Gears

- Material

- Steel

- Processing Type

- Hobbing

- Gear Tooth Profile

- Other

Gear Rack Trade Information

- Minimum Order Quantity

- 5 piece

- FOB Port

- Shenzhen

- Supply Ability

- 10000 Per Month

- Delivery Time

- 30 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Gear Rack

product Features

Precision meshing, constant transmission ratio

Based on the precise design of involute tooth shape (customizable pressure angle and modulus) and high-precision tooth grinding process, it ensures rigid meshing between rack and gear, no sliding and no backlash during work, absolute synchronization of transmission motion, and provision of constant and precise transmission ratio. Especially suitable for high-precision positioning and speed synchronization control occasions.

Excellent load bearing and anti-slip design

Thanks to the large meshing area and high-strength materials (customized alloy steel, etc.), together with the precision tooth shape and optimized tooth hardness/treatment (such as high-frequency hardening and DLC coating), the rack's ability to resist pitting corrosion and abrasion is significantly enhanced. Ensure that in high torque, heavy load transmission and transfer applications, effectively preventing slippage, jumping teeth phenomenon, reliable power transmission without delay.

Smooth operation, low noise and vibration

Through high-precision pitch control and ultra-precision grinding of the tooth surface (Ra value can be customized), the gear and rack can achieve a smooth mesh transition. Combined with optional customized tooth profile trimming (to compensate for force deformation), it effectively reduces shock and vibration, and significantly suppresses running noise. It is especially suitable for applications with stringent requirements for smooth operation and quiet environment.

Non-Standard Customization

We have no stock gear processing, only for customers to customize gear products, we can be customized according to the drawings provided by the customer to sample processing, but also according to customer demand for customers to gear drawing design and material selection.

Performance Optimization

For customer's special requirements, such as the production of racks need additional surface treatment, we can provide high-frequency quenching or DLC coating, including physical vapor deposition coating or other anodic oxidation coating treatment, to enhance the performance of the product, such as service life, hardness, oxidation resistance and so on.

Technical Parameters

|

Parameter Category |

Technical Capabilities And Scope |

Key Benefits And Details |

|

modulus |

0.1 5 M |

Precision instruments for micro transmissions, but also for heavy-duty machinery in industrial equipment |

|

Accuracy class |

ISO/GB/DIN Class 5 |

Noise transmission, high positioning repeatability, suitable for CNC machine tools, robot ground rails, precision automation systems |

|

Materials & Heat Treatment |

Multi-material solutions + custom hardening |

Material Options: Carbon Steel (45#, Quenched and Tempered Hardness HRC28-32) Alloy Steel (20CrMnTi, Carburizing and Quenching HRC58-62) Stainless Steel (SUS304/316) Engineering Plastics (PA66+GF), other materials can be provided according to customer needs Treatment process: carburizing and quenching, high-frequency quenching of tooth surface, nitriding, anti-corrosion coating |

|

Geometric specifications |

Full-dimensional customization |

Length: single 2000mm (support precision splicing). Width: 10-150mm (extendable). Overall height: 15-80mm (non-standard design). Tooth surface width: 6-100mm |

|

Critical tolerance control |

Stricter than ISO Class 5 standards |

Pressure angle: 20 standard (support 14.5, 25 and other customization). Tooth Tolerance (F): 0.015mm Tooth pitch accumulation error (Fp): 0.03mm Tooth surface roughnessRa0.8m Straightness: 0.05mm/m |

|

Load capacity |

Dynamic check based on operating conditions |

A reference value of the allowable bending stress of the material (e.g. alloy steel 300MPa) is provided and the life analysis is performed according to the load/speed/lubrication conditions |

|

Core customization capabilities |

In-depth non-standard solutions |

Special tooth profile customization (helical tooth/double arc tooth profile/tooth top modification), with positioning holes/special-shaped sections, special requirements for materials and hardness, anti-rust/wear-resistant coating treatment |

|

Detection Guarantee |

Verification of the accuracy of the whole process |

Testing equipmentZEISS CMM, Gear Inspection Machine Executive standard: ISO/DIN/GB 5 level accuracy full test |

|

Typical areas of application |

High-end industrial scenarios |

CNC machine tools, industrial robot ground rails, automated production lines, logistics sorting systems, medical equipment, heavy-duty lifting machinery |

Price 10.0 USD ($)/ piece

- Minimum Order Quantity

- 5 piece

- Supply Ability

- 10000 Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Category

Custom Metal Bevel Gear

Price 5.0 USD ($) / Piece

Minimum Order Quantity : 5 Pieces

Processing Type : Other, Bevel Gears

Color : Silver

Size : Standard Sizes

Usage : Industrial

Mop Roller Driver

Price 5.0 USD ($) / Piece

Minimum Order Quantity : 5 Pieces

Processing Type : Other, Mop Roller Driver

Color : Silver

Size : Standard Sizes

Usage : Industrial

Custom Gear Manufacturing

Price 10.0 USD ($) / Piece

Minimum Order Quantity : 5 Pieces

Processing Type : Other

Color : Silver

Size : Standard Sizes

Usage : Industrial

Custom Metal Spur Gear

Price 5.0 USD ($) / Piece

Minimum Order Quantity : 5 Pieces

Processing Type : Other, Spur Gear Shaft

Color : Silver

Size : Standard Sizes

Usage : Industrial

Send Inquiry

Send Inquiry