About 3 Axis CNC Machining

Products Features

Cost-effective

The 3-axis CNC machine has a simple structure, and its equipment acquisition, programming, operation and maintenance costs are significantly lower than that of multi-axis machine tools, and it has excellent cost-effectiveness while achieving high-precision machining, especially suitable for small and medium-sized production.

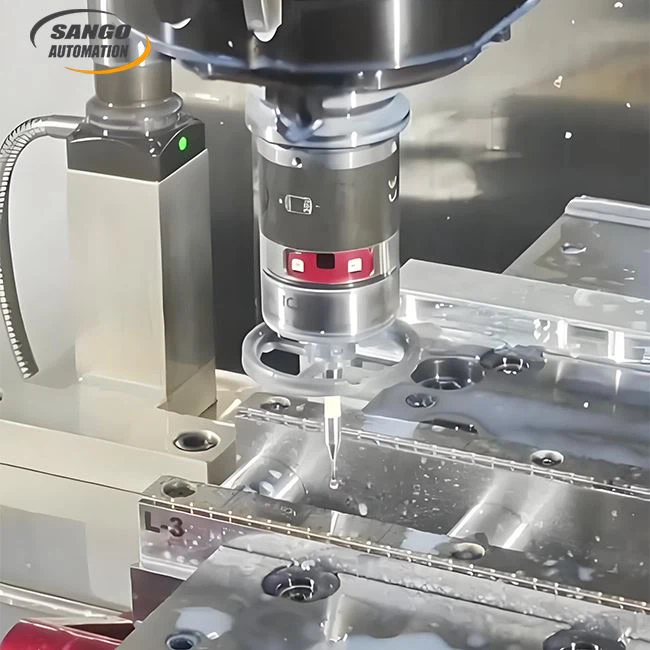

Stable and high-precision

3 Axis CNC Machining uses simple mechanical structure, good rigidity, relatively low mass of moving parts, less vibration during machining, and more stable dynamic performance during machining. After good calibration, excellent dimensional accuracy and repeatable positioning accuracy can be achieved in the three linear axes.

Wide selection of materials

The range of processing materials is extremely wide, covering most metals (e.g. aluminum, steel, stainless steel, copper, titanium alloys), engineering plastics (e.g. ABS, POM, Nylon), wood and composite materials (e.g. carbon fiber), etc.

Strong surface treatment ability

For geometric features such as planes, cavities, and contours, high-quality surface finishes (up to Ra 0.8 m or more) can be obtained by selecting appropriate tools, optimizing cutting parameters and tool pass strategies, and in some cases directly replacing subsequent finishing processes.

3 axis vs 5 axis

3 axis CNC machining and 5 axis CNC machining are two commonly used machining methods in the manufacturing industry. In short, 3-axis CNC machining is suitable for machining parts with simple structures; 5-axis machining, on the other hand, is mainly used for machining parts with complex geometries or internal cavities. The following table clearly illustrates the core differences between the two:

|

Comparison Item

|

3 axis CNC machining

|

5-axis CNC machining

|

|

Axis Of Motion

|

X, Y, Z three linear axes

|

X, Y, Z three linear axes + A, C two rotary axes

|

|

Processing Features:

|

The workpiece is fixed and the tool moves in a straight line in three directions

|

The tool and the workpiece can move at the same time and approach the workpiece from any angle

|

|

Advantage

|

Low cost and simple programming

|

One clamping can complete the processing of complex surfaces with high precision and better surface quality

|

|

Limitations

|

Complex parts need to be clamped multiple times, and each clamping requires the use of specific fixtures, which is inefficient and prone to cumulative errors

|

The cost of equipment and programming is high, and the technical requirements for operators are high

|

|

Applicable Parts

|

Plates, plates, box parts, 2D/3D contours, mold cores

|

Impellers, turbines, engine blocks, medical devices, aerospace parts, complex sculptural surfaces

|

Applications

Mold Manufacturing

In mold manufacturing, key components such as cores, cavities and bases can be manufactured using 3 axis CNC machining, such as cores, cavities and bases.

Mechanical Parts And Structural Parts

3 axis CNC machining is commonly used in the manufacture of foundational and critical components in a wide range of industrial equipment, such as motor housings, motor flanges, connection plates, gearbox boxes, pump housings, etc.

Automation And Robotics

3 AXIS CNC Machining manufactures core components for high-precision automation systems, such as aluminum frames, sheet metal parts, and slide tables and rail bases.

Automotive Industry

In the automotive industry, 3-axis machining is required from prototyping to parts production. For example, the appearance and function of the engine cover, the initial processing of tooling fixtures and transmission housings, etc.

Precision Engineering for Diverse MaterialsExperience the accuracy of 3 Axis CNC machining across metals, alloys, and plastics. Our advanced process ensures reliable, high-quality finishes every time. With expert craftsmanship and quality assurance, we serve as a trusted partner for industries requiring meticulous production and versatility.

Comprehensive Support and WarrantyWe stand behind our 3 Axis CNC machines with a one-year warranty, offering peace of mind and dependable service. As an established distributor, manufacturer, and trader in India, we commit to prompt support, ensuring you maximize productivity and minimize downtime throughout your equipment's lifecycle.

FAQ's of 3 Axis CNC Machining:

Q: How does 3 Axis CNC Machining work for metals, plastics, and alloys?

A: 3 Axis CNC Machining utilizes computer-controlled movements along X, Y, and Z axes to shape metals, plastics, and alloys precisely. The operator manually sets up the process, allowing for high accuracy and repeatability across various material types.

Q: What warranty is provided with the 3 Axis CNC machines?

A: Our machines come with a one-year warranty that covers manufacturing defects and ensures coverage for potential faults during standard usage, giving you confidence in your investment.

Q: When and where can I get support or service for the machine in India?

A: Support and service are available throughout India as we operate as a distributor, exporter, manufacturer, supplier, and trader. You can reach out to us during normal business hours for prompt assistance related to your equipment.

Q: What is the process for using a non-automated, non-remote 3 Axis CNC machine?

A: The process begins by manually loading the design and material, followed by machine setup and manual control operation. Operators oversee each stage, adjusting settings as needed to ensure precise machining results.

Q: How can 3 Axis CNC machining benefit my manufacturing operations?

A: Utilizing 3 Axis CNC machining improves product quality and efficiency, especially for complex and varied materials like metals, plastics, and alloys. Its precise control capabilities ensure high-quality outputs suitable for multiple industries.

Q: What makes your machines stand out as a distributor and supplier?

A: Our machines are built for good quality, durability, and consistent performance. As a reputable distributor and supplier in India, we provide comprehensive customer support and ensure that clients receive value-added services alongside their purchase.

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese