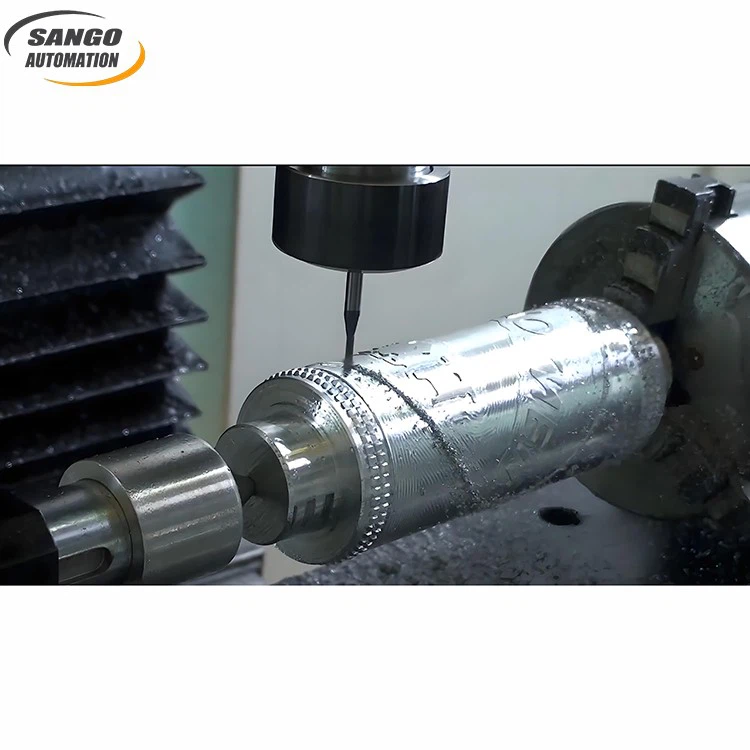

About 4 Axis CNC Machining

4-Axis CNC Machining Features

More Flexibility

The rotating fourth axis allows the machining machine to flexibly handle workpieces of various shapes and sizes, such as curved surfaces, inclined holes, bevels, tapers, etc.

Higher Efficiency

Four-axis machining can complete the processing of multiple side and angle features of the workpiece in a single clamping, saving time on fixture changes and downtime, and improving machining efficiency.

High Processing Accuracy

4 Axis CNC Machining Parts tend to have high accuracy because all axes of the four-axis machining machine are controlled automatically, reducing manual intervention and errors, and achieving higher machining accuracy than traditional methods when machining products with complex surfaces, with an error of 0.005mm.

Disadvantages of 4-axis machining services

Limited Geometry

Four-axis machining can achieve the processing of most shapes of workpieces, but complex structures such as impellers and special-shaped connector housings can only be realized by five-axis machining, not four-axis machining.

Expensive Cost

The cost of four-axis machining machine tools is more expensive than ordinary CNC machining equipment, and the maintenance cost of machine tools and tools is also a big expense.

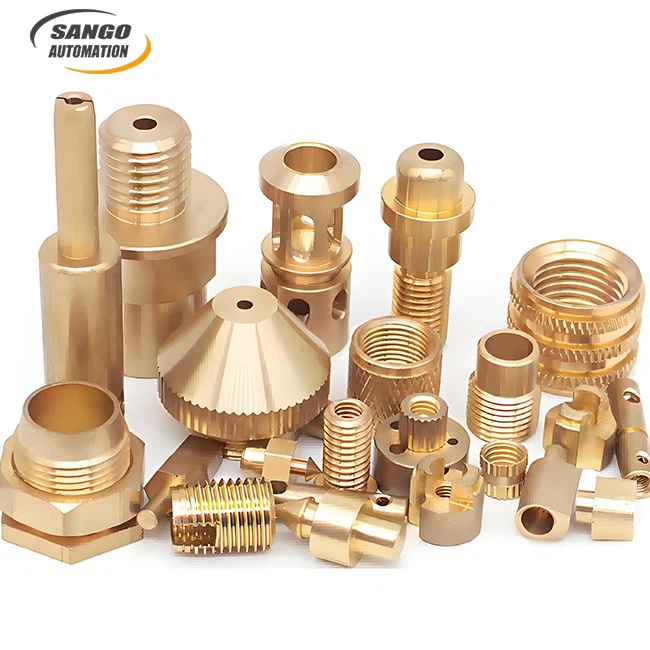

Applications

|

Applications

|

Typical parts

|

Core processing advantages

|

|

Industrial manufacturing

|

Camshaft, turbine blades, gearbox housing

|

Multi-sided milling/drilling is completed in a single clamping with an accuracy of 0.02mm.

|

|

Aerospace

|

Titanium alloy rib plates of the wings, tongue and groove of compressor blades

|

Linked processing of weight-reducing surfaces, the efficiency is increased by 40% compared to 3 axes.

|

|

Medical devices

|

Artificial joints (acetabular cups), surgical instrument fittings

|

Avoid secondary clamping pollution, and increase the yield of titanium alloy multi-angle grooving by 20%.

|

|

Energy & Automotive

|

Impeller runner, differential casing oblique oil hole

|

Closed impeller runner machining (replaces 5-axis) with 40% cost reduction.

|

Exceptional Industrial-Grade PerformanceDesigned specifically for heavy-duty industrial use, this 4 Axis CNC machine delivers consistent and precise machining capabilities. With its premium metal construction and standard sizing, users benefit from a robust solution that meets demanding production environments across India.

Reliable Warranty and SupportPurchase with confidence thanks to a comprehensive 1-year warranty. Our team ensures smooth after-sales support, offering guidance and maintenance services throughout India to keep your operations running efficiently.

Versatile Application and DistributionAs a leading distributor and exporter, we supply these machines to manufacturers and traders nationwide. Whether you are upgrading production lines or starting new projects, our CNC machines are built to adapt to a variety of industrial machining tasks.

FAQ's of 4 Axis CNC Machining:

Q: How is the 4 Axis CNC machine operated, and does it require remote control?

A: The 4 Axis CNC machine is manually operated and does not come with remote control functionality. Its design emphasizes hands-on operation, allowing users precise control during industrial machining processes.

Q: What does the 1-year warranty cover for this CNC machine?

A: The 1-year warranty covers manufacturing defects and certain hardware issues, ensuring peace of mind for users. For warranty service, customers can contact our support team anywhere in India for prompt assistance.

Q: When should maintenance be performed on the 4 Axis CNC machining system?

A: Regular maintenance is recommended after every major machining cycle and periodic inspections should be scheduled every three to six months, depending on usage intensity, to ensure optimal performance and machine longevity.

Q: Where is this 4 Axis CNC machine available for purchase or distribution?

A: We distribute, export, and supply this CNC machining solution all over India through our established network. Interested customers can reach out to our sales team or authorized dealers for purchasing information.

Q: What is the process for installing and setting up the machine?

A: Installation involves positioning the machine at your site, connecting to the required power supply, and ensuring all safety protocols are followed. Our technical team provides guidance during initial setup to help customers get started efficiently.

Q: How can this machine benefit my industrial operations?

A: With its high-quality construction and standard size options, the 4 Axis CNC machine enhances manufacturing precision, boosts productivity, and reduces material waste, making it a valuable asset for various industrial applications.

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese