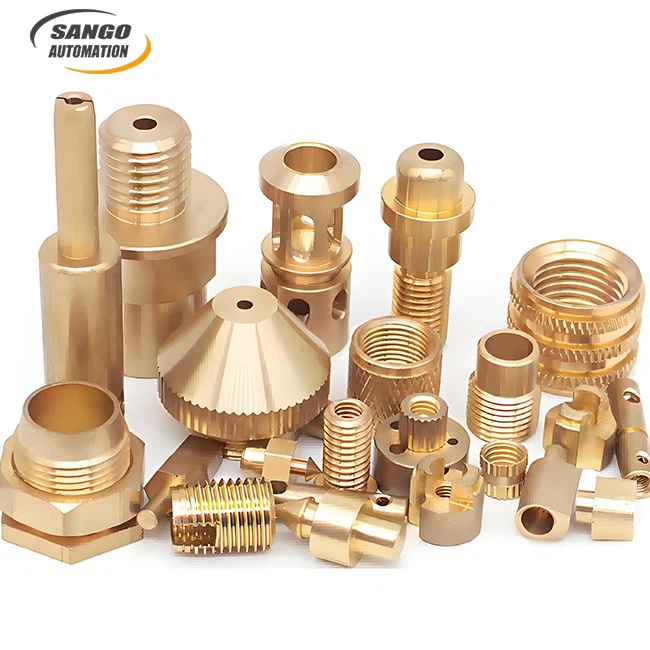

About Brass CNC Machining Services

Why choose Hansheng Automation as your brass parts supplier?

Ultra-High Tolerance Control

Our machining quality is defined by the exacting standards used in manufacturing P0-class planetary reducers. When we apply 0.002mm precision to brass machining, every part you create will have a perfect fit and reliability.

Ultimate Processing Efficiency and Cost-Effectiveness

Our advanced CNC machine fleet unleashes the full potential of brass cutting, enabling high-speed, efficient production. This means faster delivery times and more attractive pricing, especially for high-volume orders of brass screw machined parts & components.

Expertise in Complex Structures

From valve bodies with internal cross-hole systems to precision threaded connectors, our ability to handle complex geometries is proven. We specialize in manufacturing a wide range of brass components and brass turned parts, ensuring consistent quality, no matter how complex the structure.

One-Stop Integrated Manufacturing Services

We provide seamless services from casting blanks to final precision-finished products. This "casting + finishing" model can simplify the supply chain for your project and significantly reduce the material cost of large or special-shaped Brass Turning Parts.

Products Features

Dimensionally stable

Highly smooth surface finish

High electrical and thermal conductivity

Excellent corrosion and wear resistance

Technical Parameters and Capabilities

| Item |

Capability |

Value |

| Machining Precision |

0.002mm 0.01mm |

Meet the requirements of all grades from ordinary hardware to precision instruments. |

| Turning Diameter Range |

3mm - 300mm |

Cover micro to medium-sized Brass Turned parts Components. |

| Surface Roughness (Ra) |

Up to 0.2m |

Achieve mirror effect without additional polishing. |

| Core Processes |

CNC turning, milling, drilling, tapping, knurling, precision grinding |

Provide a complete CNC machining brass parts solution. |

| Equipment |

Brother high-speed drilling and tapping centers, multi-axis turning and milling centers |

High efficiency, high precision, high stability. |

| Supported Materials |

Brass, red copper, bronze, aluminum, stainless steel, etc. |

Provide diversified material choices according to your needs. |

Professional copper alloy processing capabilities: brass and copper

Brass

Main grades include C36000 (HPb59-1), C26000 (H70), C28000 (H62), etc. We provide a full range of Copper & Brass Turned Parts services.

Copper

Grades such as C11000 and C10100. With extensive experience, we provide reliable CNC Machining Copper Services, especially when dealing with pure copper's high thermal conductivity and easy knife sticking properties. As a leading Copper CNC Machining Services In China supplier, we ensure your copper parts have optimal conductivity and dimensional accuracy.

Precision Engineering for Industrial NeedsOur Brass CNC Machining Services cater to the demanding requirements of industrial applications. Utilizing state-of-the-art CNC technology, we deliver components that achieve exceptional accuracy and consistency. Each piece is produced in standard sizes to simplify integration into your production lines, ensuring efficiency and operational smoothness.

One-Year Warranty for ConfidenceEvery brass component we supply comes with a one-year warranty, emphasizing our commitment to product reliability. This warranty period covers manufacturing defects, offering clients peace of mind. Our approachable support team in India is always available to address any concerns or assist with warranty claims.

Reliable Supply and Distribution Across IndiaAs a leading manufacturer, distributor, exporter, supplier, and trader, we ensure a seamless supply of brass CNC machined components across India and abroad. Our comprehensive distribution network guarantees timely delivery and dependable service, keeping your operations running smoothly.

FAQ's of Brass CNC Machining Services:

Q: How does the warranty for your brass CNC machining services work?

A: Our brass CNC machined components come with a one-year warranty covering manufacturing defects. If any issues occur within this timeframe, contact our customer support in India for prompt assistance and resolution.

Q: What sizes of brass components are available through your CNC machining services?

A: We supply standard-sized brass parts, designed for easy integration in various industrial applications, ensuring compatibility and streamlined assembly.

Q: When can I expect delivery after placing an order?

A: Delivery times depend on your location and order size. As a distributor and supplier in India, we prioritize quick dispatch and efficient logistics to ensure your components arrive promptly.

Q: Where are your brass CNC machining services offered?

A: Our services and products are available across India and for export. With a strong distribution network, we cater to the needs of industries both domestically and internationally.

Q: What is the process for ordering custom or bulk brass CNC machined parts?

A: To place an order, simply contact our sales team with your specifications and quantities. We provide quotations, timelines, and ensure smooth order processing from manufacturing to delivery.

Q: How are your brass CNC machined components used in industrial settings?

A: Our brass components are utilized in various industrial environments, from machinery assemblies to electrical fittings, offering resistance, durability, and precise fit for demanding tasks.

Q: What are the benefits of choosing your brass CNC machining services?

A: Clients benefit from reliable product quality, comprehensive after-sales support, a one-year warranty, and efficient supply chains, making us a trusted partner for industrial brass solutions.

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese