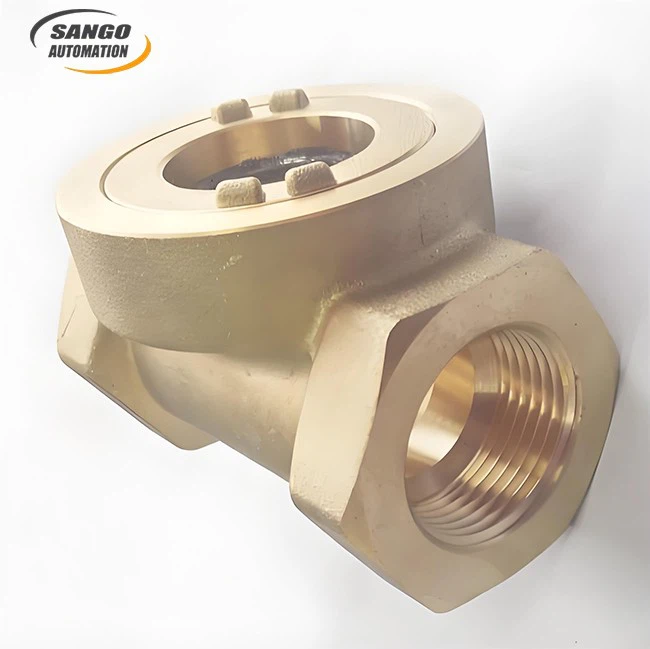

About Custom Brass Casting

Product Characteristics

Customizability

Brass material has low viscosity and good fluidity after melting, and can be used to fill a variety of complex custom shapes.

Corrosion Resistance

The brass material used in custom brass casting creates a dense oxide film on the surface, and other metal elements are added during melting to enhance the corrosion resistance of the brass material.

Other Characteristics

Custom brass casting parts have excellent mechanical properties, such as good hardness and strength, and good toughness and wear resistance, and perform well in some heavy-duty applications.

Material Selection

There are many materials that can be selected for custom brass casting, and the following categories can be mainly selected according to the content of copper and other metal elements in the composition.

|

Name And Grade

|

Key Ingredients

|

Peculiarity

|

Typical Applications:

|

|

Free-Cutting Brass

(C3604 / C36000)

|

With: 60.0-63.0%

Pb: 1.8-3.7%

Zn: Redundancy

|

The cutting performance is very good, it can be machined at high speed, and the surface finish is good. Moderate strength and hardness.

Note: Contains lead and is not intended for use in drinking water systems.

|

A large number of structural parts that need to be turned and milled are required, such as valves, gears, pipe joints, and electrical parts.

|

|

Manganese Bronze

(C86300)

|

With: 60.0-66.0%

Al: 5.0-7.5%

Fe: 2.0-4.0%

Mn: 2.5-5.0%

Zn: Redundancy

|

It belongs to the heavy-duty alloy. It has the characteristics of high strength, high hardness, wear resistance and good corrosion resistance.

|

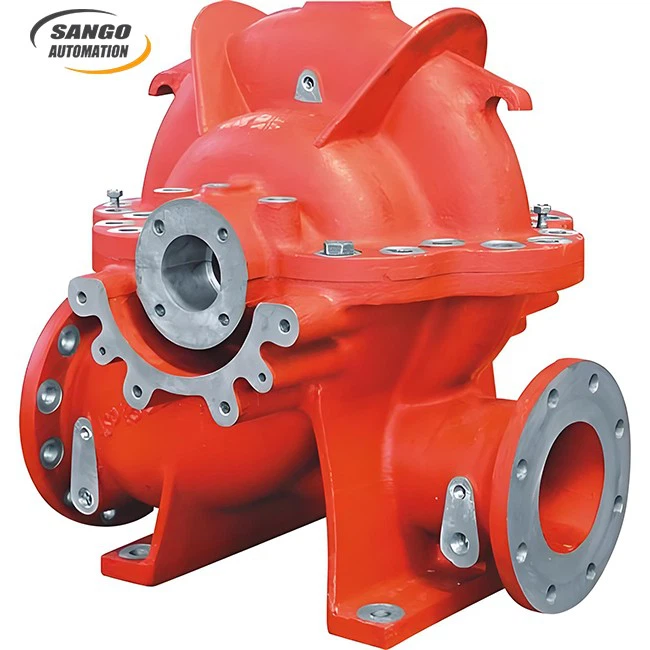

Heavy machinery gears, worm gears, marine propellers, high-strength bearings, valve stems, pump housings.

|

|

Silicon Brass

(C87500)

|

With: 80.0-90.0%

Yes: 3.5-5.5%

Zn: Redundancy

|

The casting fluidity is good, suitable for thin-walled complex castings, and the surface oxide film has high density, making it better corrosion and wear resistance.

|

Complex thin-walled parts, high-grade bathroom accessories, ship accessories, corrosion-resistant pumps, valve components.

|

|

Admiralty Brass

|

Cu: Approx. 71.0%

Sn: 0.9-1.2%

Zn: Redundancy

|

The addition of tin (Sn) to the composition improves the corrosion resistance of dezincification, and is widely used in the maritime field.

|

Marine equipment, marine valves, heat exchanger tubes, power plant condenser tubes.

|

|

Red Brass

(C83600)

|

With: 83.0-88.0%

Sn: 3.5-5.0%

Pb: 1.0-3.0%

Zn: Redundancy

|

It has a high copper content, a reddish color, and good corrosion resistance. It has both good casting and machining properties.

|

Traditional bathroom faucet valve body, low-pressure valve, pipe fittings, building hardware, decorations.

|

|

Tin Bronze

(C90500)

|

With: 86.0-89.0%

Sn: 9.0-11.0%

Zn: 2.0%

|

Good wear resistance (especially suitable for sliding friction), good self-lubrication, and strong corrosion resistance.

|

Bearings, bushings, worm gears, gears, corrosion-resistant pump bodies, art sculptures.

|

|

Aluminum Bronze

(C95400)

|

Cu: Margin

Al: 10.0-11.5%

Fe: 3.0-5.0%

|

It has excellent mechanical properties such as strength, hardness, and wear resistance. Its resistance to corrosion and high-temperature oxidation far exceeds that of ordinary brass.

|

Heavy-duty wear gears, valve assemblies, nuts, screws, extrusion dies, marine application hardware.

|

Customized Processes

The process of Custom Brass Casting is not complicated, but the main thing is to determine the requirements and materials used so that the engineer can choose the best production option. Below is the entire customization process for Custom Brass Casting.

Demand Confirmation

Our engineers will communicate with you in detail to determine your needs, including quantity, material, estimated delivery time, your product drawings, casting process options, and the price after evaluation by our engineer team.

Pattern Making

Based on the data in the drawing design and the casting process determined after the final evaluation, the most appropriate method for manufacturing the pattern is selected. For example, lost wax casting produces wax molds coated with refractory materials, while sand casting makes metal molds that are consistent with the shape of the part and have some margin reserved.

Molding

The molding process of different casting processes is different from the molding process made by the mold. Lost wax casting mainly melts the wax out of a wax mold coated with refractory coating at high temperatures, so that it forms a cavity shell that is consistent with the shape of the part. Sand casting, on the other hand, uses the upper and lower parts of the sand box to prepare a cavity that is consistent with the shape of the pattern.

Melting and Casting

After the pattern and mold are ready, it is time to melt the brass material and cast it, and the molten metal liquid is slowly injected into the cavity through the pouring system to wait for cooling and solidification.

Demolding and Post-Processing

After the casting solidifies, the casting is taken out by destroying the shell, and at this time, only the process of making the casting blank is completed, and the casting precision processing and other post-processing operations need to be carried out according to the size requirements of the drawings.

Quality Inspection and Delivery

After completing all the production work, our quality inspection team will conduct quality inspection on the products produced, and the qualified products will be delivered to customers by sea, land and air according to the prescribed packaging.

Precision Brass Castings for Industrial ApplicationsOur custom brass castings are crafted from carefully selected alloys, including Admiralty Brass, C3604, and C86300, which provide excellent machinability and strength. We supply these premium products to clients across India, tailored to your exact specifications for consistent performance and reliability.

Quality Assurance and Trusted ExpertiseWith a strict focus on quality, every brass casting undergoes rigorous inspections and is backed by a one-year warranty. As experienced manufacturers, suppliers, exporters, and traders, our commitment is to deliver only the best, supporting our customers with reliable products and comprehensive service.

FAQ's of Custom Brass Casting:

Q: How is custom brass casting carried out with materials like Admiralty Brass, C3604, and C86300?

A: Custom brass casting involves melting and pouring chosen alloys such as Admiralty Brass, C3604, or C86300 into tailored molds. This process ensures that each component meets specific client dimensions and quality requirements, resulting in precise, robust castings.

Q: What benefits do Admiralty Brass and C3604 castings offer over standard brass types?

A: Admiralty Brass offers enhanced corrosion resistance, especially in marine environments, while C3604 provides excellent machinability. Both materials yield durable, high-quality castings ideal for various industrial and engineering applications.

Q: When can I expect the warranty coverage to start for my custom brass castings?

A: The one-year warranty begins from the date of delivery, ensuring our customers are protected against material or manufacturing defects within this period. Our service team remains available to address any concerns during the warranty timeframe.

Q: Where are your brass casting facilities located, and do you supply throughout India?

A: Our brass casting facilities are based in India, and we supply products nationwide. As a manufacturer, distributor, exporter, supplier, and trader, we cater to clients across diverse regions and industries throughout the country.

Q: What is the process for placing an order for custom brass castings?

A: To place an order, simply contact our team with your technical specifications and material requirements. We will guide you through the design, quoting, and manufacturing stages to ensure your castings are tailored to your needs.

Q: How should customers use and maintain these custom brass castings for optimal performance?

A: Usage guidelines depend on your specific application. However, keeping castings clean, dry, and free from corrosive elements helps maintain performance. Regular inspection for wear or damage also extends component lifespan.

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese