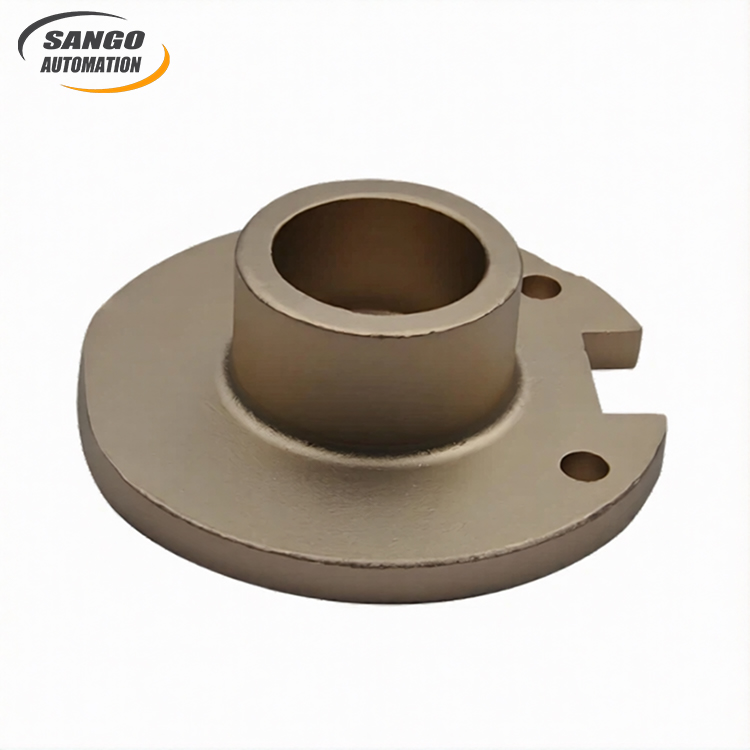

About Housing Casting

Product Features

1. Cost Savings

Through sand casting, the integrated production of gearbox housing can be realized, which saves materials and cutting time compared to CNC machining.

2. Material Diversification

It supports a variety of material options, such as gray cast iron, ductile iron, cast alloy steel, carbon steel, cast aluminum, etc., and the appropriate material can be selected according to the specific working conditions of the shell.

3. High Product Accuracy

Our Casting Blank Manufacturing is able to achieve a free tolerance of 1mm, while Castings Precision Machining is able to achieve a specific tolerance of 0.03mm.

4. Customized Production

The shell casting we can achieve includes: motor housing, reducer housing, gearbox housing and other various housings. As long as you provide the drawings of the shell products you need to cast and the materials that are marked to be produced, we can customize the production for you.

Parameter

|

Parameter Items

|

Reference Value

|

Illustrate

|

|

Maximum unit weight

|

3000 kg

|

Sand casting is suitable

|

|

Minimum wall thickness

|

Aluminum: 4 mm; Iron/steel: 6 mm; Copper: 5 mm

|

Complex structures need to be thickened

|

|

Surface Roughness (Ra)

|

Casting: 12.525 m Machining: 0.83.2 m

|

Mirror processing up to Ra0.8 m

|

|

Casting state tolerance

|

1.0 mm

|

Dimensions 1 m (+0.5 mm tolerance for every 1 m increase)

|

|

Precision machining tolerances

|

0.03 mm

|

Bearing holes/sealing surfaces and other key mating positions

|

|

Supporting materials

|

Ductile Iron (QT450-10/QT600-3)

Grey Cast Iron (HT200/HT250)

Cast Steel (ZG270-500/ZG310-570)

Cast Aluminum (A356/ADC12)

Cast Copper (C86300/C95200)

|

Tensile strength coverage:

160900 MPa

|

|

Optional process

|

Sand casting

Lost foam casting

Gravity casting

|

Sand mold: low-cost batches

Lost foam: complex cavity

Gravity: Thin walls are dense

|

Applications

Robotics

Robot arms often need to reserve internal space to facilitate wiring, such as joints and arms in Scara robots, surgical robots or industrial robotic arms, and other shell parts, which are usually produced by casting.

4-Axis & 5-Axis Machining Machines

The fourth and fifth axes in this machine are achieved by means of a swing-type connecting shaft housing assembled with two hollow rotary tables, which are cast using a casting process that reduces material waste.

Gearbox Field

The housing of cam indexer, planetary gearbox and other reducers is cast with gray cast iron, which can improve the compressive strength, durability and shock absorption performance of the housing, and can also save costs.

Electromechanical Products

The gearbox shell and motor shell in mechanical and electrical products can be mass-produced by shell casting. To better produce these products with complex internal space, die-casting is often used.

Reliable Quality and VersatilityManufactured with high-quality materials like aluminum, iron, steel, and copper, our housing castings ensure excellent durability and performance across different industrial sectors. The standard sizes make them adaptable for multiple uses, while the 1-year warranty demonstrates our confidence in the product's longevity. Our meticulous quality control guarantees you receive castings that meet industry standards and your specific needs.

Serving Indian and Global MarketsAs dedicated distributors, exporters, manufacturers, suppliers, and traders based in India, we reach both domestic and international clients with competitive service and consistent product availability. Our commitment to prompt delivery and comprehensive after-sales support sets us apart in the industry, making us a preferred choice for businesses seeking reliable housing casting solutions.

FAQ's of Housing Casting:

Q: How do I select the right size of housing casting for my application?

A: Housing castings are offered in standard sizes designed to fit a range of industrial requirements. To choose the appropriate size, consider your project's technical specifications and consult our team for guidance based on the material and usage.

Q: What materials are used in your housing castings?

A: Our housing castings are made from high-grade aluminum, iron, steel, and copper, ensuring robust construction and long-lasting performance suitable for demanding environments.

Q: What is the process involved in manufacturing these housing castings?

A: The casting process involves precision molding using quality metals like aluminum, iron, steel, or copper. Each unit undergoes rigorous quality checks from casting to finishing to ensure high standards are maintained throughout production.

Q: When can I expect delivery after placing an order?

A: Delivery timelines depend on order quantity and location. For standard sizes, we aim to process and ship orders promptly, typically within a few working days for domestic clients. International shipping may take slightly longer, depending on logistics.

Q: Where are your housing castings manufactured and distributed from?

A: Our housing castings are manufactured in India and distributed both domestically and to international markets. As established exporters, distributors, and suppliers, we ensure broad accessibility to our products.

Q: What are the benefits of using your housing castings?

A: Using our housing castings offers benefits such as robust construction, reliable quality, compatibility with a range of industrial applications, and a 1-year warranty for peace of mind.

Q: How can these housing castings be used in industrial projects?

A: These castings are suitable for various machine enclosures, protective housings, and structural support components in industrial settings. The standard design and high-quality materials make them versatile for diverse applications.

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese