About Titanium CNC Machining Services

Why choose Hansheng Automation as your titanium alloy processing partner?

Ultra-High Precision

Hansheng Automation's manufacturing portfolio includes harmonic reducers and planetary gearboxes with micron-level tolerances. These technological strengths demonstrate our full capability to provide titanium alloy machining services, achieving ultra-mirror-like precision of 0.002mm.

Experience in Complex Structural Parts

From gear contours to intricate internal structures, we excel in handling a wide range of non-standard, complex custom parts, whether thin-walled, curved, or requiring multi-axis machining.

Integrated Casting and Finishing

For large or near-net-shape titanium alloy parts, our unique "casting + finishing" approach significantly reduces expensive material waste and shortens machining cycles, providing you with highly competitive cost solutions.

Quality Assurance

As a leading manufacturer, we understand that the quality of each product represents our reputation. We maintain a comprehensive quality management system to ensure that every Custom CNC Titanium Part meets the highest standards.

Products Features

After our precision machining, each of your CNC Titanium parts will offer the following advantages.

Excellent strength-to-weight ratio

High corrosion resistance

Biocompatibility

Excellent high and low temperature resistance

Excellent surface finish

Our CNC Machining For Titanium Parts

| Machining Item |

Tolerance Capability |

Remarks |

| Ultra-Mirror Machining |

0.002mm |

Suitable for parts with ultra-high precision requirements such as optics and sensors |

| Precision Turning/Milling/Grinding |

0.005mm |

Meet the tolerance requirements of most aerospace and medical parts |

| General Turning and Milling |

0.01mm |

Cost-effective standard precision machining |

| Gear Manufacturing |

ISO / DIN level 5 |

Can manufacture high-precision titanium alloy gears and spline shafts |

| Casting Specified Tolerance |

0.03mm |

Provide high-precision blanks for subsequent finishing |

| Maximum Machining Size |

2100 x 1060 mm |

Cover the machining needs from micro parts to medium and large structural parts |

Our Manufacturing Process

Technical Evaluation and Quote

Upload your CAD drawings (supporting STP, IGS, X_T, SLDPRT, etc.), and our team of engineers will conduct a process evaluation and provide a quote within 24 hours.

Process Programming and Optimization

Based on the characteristics of titanium alloys, we use professional CAM software to program and optimize tool paths, cutting speeds, and cooling schemes.

Precision Machining and Manufacturing

Experienced technicians operate advanced CNC equipment in our temperature-controlled workshop.

Full-Dimensional Quality Inspection

Utilizing equipment such as coordinate measuring machines (CMMs) and gear testers, we rigorously inspect finished products for dimensional and geometric tolerances.

Safe Packaging and Delivery

Finished products are professionally cleaned and packaged to ensure safe and intact transportation and on-time delivery.

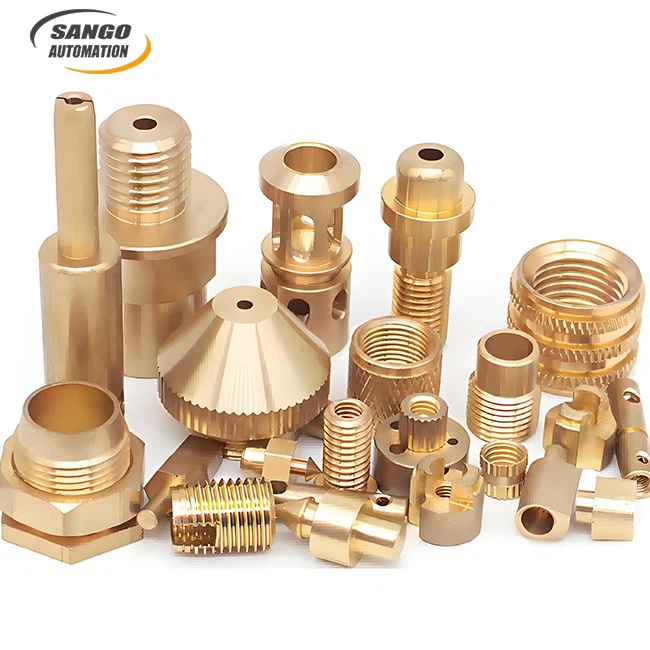

Premium Titanium Components for IndustryOur CNC machining services utilize high-grade titanium to produce components with outstanding strength-to-weight ratios and corrosion resistance. Each part undergoes precise computer-controlled milling and cutting, ensuring it meets rigorous industrial standards. Available in standard sizes, our offerings are ideal for sectors requiring durable and performance-driven metal parts.

Comprehensive Support from IndiaAs a full-scale distributor, exporter, manufacturer, supplier, and trader in India, we provide end-to-end support for your titanium component needs. Our team guides you from initial consultation through production to after-sales service, making us a trusted partner for clients seeking reliable industrial solutions.

FAQ's of Titanium CNC Machining Services:

Q: How are titanium CNC machined components used in industrial applications?

A: Titanium CNC machined components are widely used in industrial settings where high strength, low weight, and corrosion resistance are required, such as machinery, fixtures, and equipment that experience demanding operating conditions.

Q: What is the CNC machining process for titanium parts?

A: CNC machining for titanium involves computer-controlled cutting, milling, and drilling operations. This process ensures precise shaping and finishing of titanium components, which are produced according to exact specifications and standard sizes.

Q: When is it beneficial to choose titanium CNC machined parts?

A: Titanium CNC machined parts are beneficial when your application demands high durability, corrosion resistance, and weight savings without compromising structural integrity. They are ideal for harsh industrial environments and long-term use.

Q: Where are your titanium CNC machining services available?

A: Our services are based in India, from where we serve domestic and international clients as a manufacturer, supplier, exporter, distributor, and trader of titanium components.

Q: What warranty is provided with your titanium CNC machined products?

A: We provide a one-year warranty with all our titanium CNC machined products, assuring you of their quality and our commitment to customer satisfaction.

Q: How can I be sure of the quality of your titanium CNC machining services?

A: All parts are manufactured from high-quality titanium under stringent quality control processes, ensuring they meet industrial performance standards and deliver reliable results.

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese